Miniaturisierte Energiewandler

Recent German demographics shows that 21% of the total population are older than 65 years. This number is predicted to increase to over 30% by year of 2050. The increasing number of elderly people together with the increasing life expectancy motivates the development of implantable medical devices (IMD). A key challenge for these IMDs is their limited battery capacity. It is essential to develop an alternative energy supply mechanism for the IMDs.

Energy harvesting technologies have attracted considerable attention in the past decade. Various applications exist together with dedicated energy harvesters to address the growing demand of ubiquitous electronic systems. Miniaturized energy harvesters, which integrated in the medical devices shall support the battery, and thus prolong the implant's lifetime.

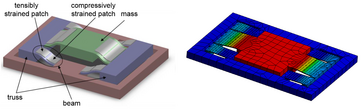

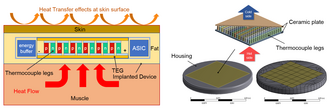

In this proposal, the piezoelectric energy harvester, which harvests wasted mechanical vibration energy, and the thermoelectric generator, which harvests human body thermal energy, are studied. To design and optimize these energy harvesters, computer-aided development processes have become state-of-the-art because of their low cost and high efficiency. However, the capacity of today’s computers is not always sufficient to meet the demands of industrial simulations. The complex geometry and multi-physics effects in energy harvesting devices have led to rather time-consuming simulations. To improve the efficiency of the simulations using existing computers, the methodology of model order reduction (MOR) and parametric model order reduction (pMOR) methods are applied to generate reduced order models, which guarantee computational efficiency, e.g., for the system-level simulations by replacing the original full-scale model with the reduced but still accurate surrogate.

Mitarbeiter

Chengdong Yuan, M.Sc.

Tel: 04421 985-2354

✉ E-Mail

Raum L 236